Humidity of wood in the production and manufacture of interior doors

The moisture content of the wood has a direct impact on the quality of the doors that are made from it. Experts have been struggling with this problem for a long time. Due to changes in the humidity of the wood, the dimensions of the parts of the door structure made of it change. Real craftsmen have found effective ways to overcome this lack of wood in the production of interior doors

There is an effective way to protect any elements made of wood from changes in size that occur with changes in humidity. "Chemical stabilization" is a technique that has been widely known for a long time. It is an impregnation of wooden parts with chemical compositions. The most popular of them are polyethylene glycol, methyl methacrylate, phenol-formaldehyde. This is a time-consuming method. Its implementation requires significant costs, both time and financial. This is why chemical stabilization is not so widespread.

In large industries, the problem of changing the size of the tree is solved by structural methods. Surely everyone has seen wooden furniture at least once, the age of which speaks for itself. Even after hundreds of years, it does not lose its appeal. That is, the skill of the manufacturer was at the highest level. The design of a piece of furniture is based on the ability of its parts to adapt to changes in air humidity.

A striking example of combining functional features and aesthetic characteristics is the frame-panel design. Several centuries ago, carpenters came to the conclusion that to maintain the shape of a regular rectangle over a long period of time, the use of longitudinal slats of adjusted dimensions is ideal.

In the space between the paneled slats, panels made of wood are placed, which, during long-term operation, are one hundred percent likely to fall into different humidity conditions, and, consequently, will change their size. If you cut the edges of each panel slightly at a slight angle, it will move freely in the frame when it swells and shrinks. The bevel is made wide so that it is invisible to the naked eye.

Such a wooden structure is considered basic. It is used not only in the manufacture of door panels, but also in the decoration of walls with wooden panels, in the manufacture of various pieces of furniture.

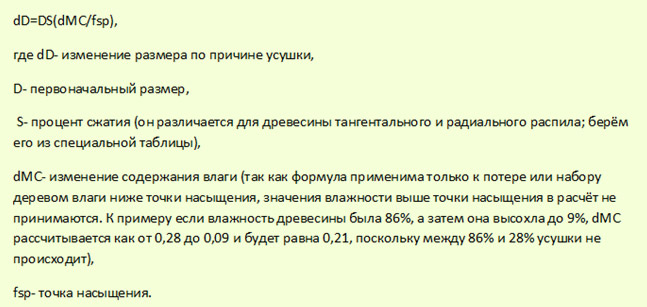

The classic model involves fixing a wooden panel to the frame structure in the center of the lower and upper slats. Thus, the part can move freely between the right and left bars. In the old days, the masters determined the amount of the necessary gap "by eye". Today, a special shrinkage formula is used, which allows you to determine the size of the gap.

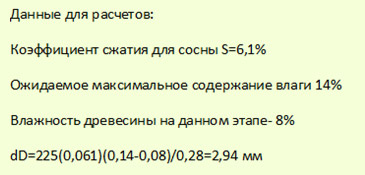

You can give an example of the calculation for a door made of solid pine with panels of 450 mm in size. A gap of too small size in such a design will lead to irreparable consequences: the functional characteristics and aesthetic appeal of the door will be lost after a short time.

That is, a gap of 3 mm will be quite enough for such a design.

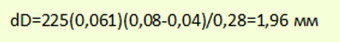

When the moisture content of the wood is 4%

The gap between the joints should allow the panels not only to expand, but also to become smaller in size. Each part is painted separately, because when you change their size, the unpainted areas will be visible.

Inexperienced carpenters can simply copy the model by its appearance, without resorting to complex calculations. In this case, you are waiting for trouble. In summer, the panels may well crack, and in winter and autumn-swell from high humidity, which will lead to a break in the frame. Today, many wooden parts used for the production of door panelsare made from alternative materials – metal, plastic, and others.

But still, today it is wooden structures that are most popular. Wood has been used in construction since time immemorial. This is the most affordable material to meet human needs. Together with the skills of making wood products, aesthetic characteristics develop. Nowadays, the emphasis is on mass production. This has led to the fact that many of the products offered for sale do not have the special energy, sensuality inherent in natural materials. So the natural wood mass and the manual work on its processing are appreciated at the highest level.

Pub date: 2021.06.01